| story by | |

| photos by | Steven Hertzog |

| OPEN A PDF OF THE ARTICLE |

Advancing technology has reinvented the automobile industry and, thus, the requirements of the trade.

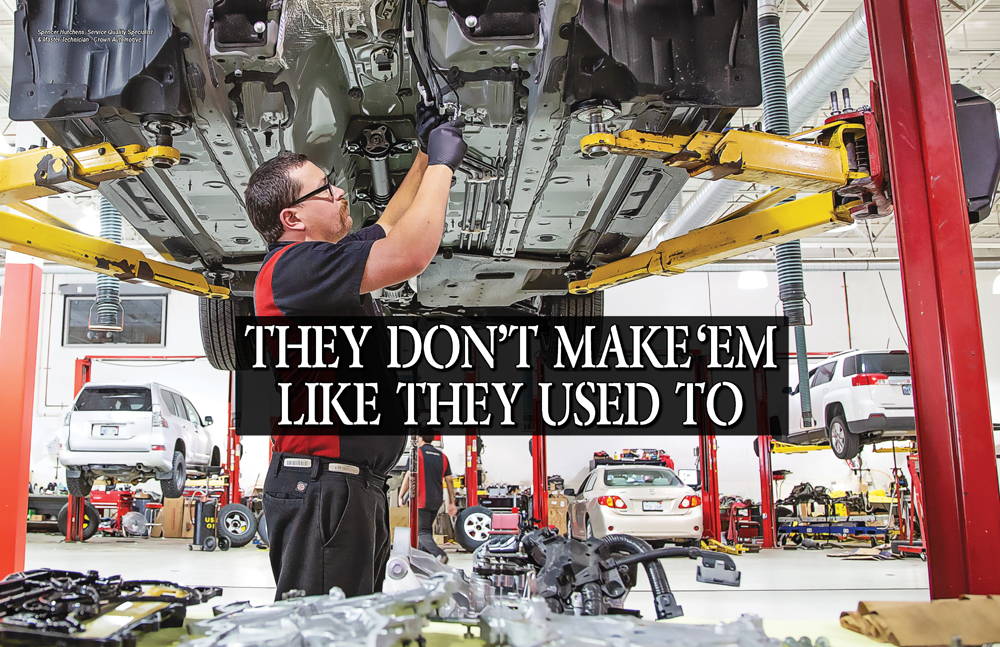

Spencer Hutchens, Service Quality Specialist & Master Technician – Crown Automotive

The COVID-19 pandemic and ensuing shutdown early in 2020 effectively turned the world of business upside down. Employees were all but confined to home, factories ground to a halt—the world stopped.

The automotive industry was not immune to any of it. Plants overseas that made computer chips now required in ever-more-complicated car and truck engines ceased production and closed. Not that new autos were needed now that it seemed most everyone was staying home and off the roads. Even the automotive trades—specifically auto technicians, the modern-day job title of what once were mechanics—suffered from some leaving the workforce along with fewer numbers coming into training programs, leading to the same kind of staff shortages suffered in so many industries today.

It’s been a rough three years. But at least one local expert in the field never had a doubt the automotive service industry and automotive trades would bounce back, and in a big way.

“People have to drive,” says Ginger Lopez, service and parts director at Crown Toyota. “For this industry, that’s it. No matter what else happens, people still need their cars.

“Auto service remains steady,” she adds.

Not that there haven’t been challenges. The U.S. Bureau of Labor Statistics forecasts “little to no change” from 2021 to 2031 in the demand for automotive service techs. But change is coming. Car and truck engines are becoming ever more technical and computer driven. It’s widely believed that within 10 years, one-third of all cars and trucks on the road will be all-electric vehicles that require less maintenance.

“It’s changed a lot,” says Lopez, who has 38 years of experience in the industry. “The tech of 30 years ago is hardly interested in working on these cars today.

“Recruiting has been a challenge,” she continues. “Over the last 15 years, the number of applicants is down. More seem to push to (information technology) jobs.”

Despite the challenges, though, Lopez says her team of techs remains fully staffed, with 20 technicians working in 20 service bays in Crown Toyota’s spacious garage, on the south end of Iowa Street.

“We work hard on retention and keeping our people,” she explains, adding that Crown participates in Toyota’s T-Ten Program in Omaha, which allows aspiring techs to pursue a two-year associate’s degree in automobile technology, as well as become fully certified, at no cost to them.

“People’s ears perk up when they find out they can learn on the job without going into debt,” says Jaime Llamas, human resources director at Crown Toyota. “It seems like everything is a bit better now. So many people were affected by COVID. But now, people are getting back to work and getting more comfortable.

“I feel like we’re in a good place, and it’s picking up,” he says.

top to bottom: Crown Automotive: Ginger Lopez, Service & Parts Director consults scheduling with Chris Schermbeck, Service Dispatcher; Spencer Hutchens rebuilding an engine; Ryan Wingert, Assistant Service Manager going over a diagnostic report with Alec Hopson

Grease Monkey to Computer Engineer

Twenty years ago, give or take, auto technicians were endearingly often referred to as “grease monkeys.” They’d spend much of their days working power wrenches and wiping equipment down with oil rags.

Today, they might be able to work for NASA. Vehicles have become so sophisticated and advanced, loaded with computers and technology, that having advanced knowledge in programming and computer maintenance is more important than how a carburetor moves gas through an engine or how pistons fire.

Rollie Stallbaumer, service manager for three Laird Noller dealerships in Lawrence, pulls out his smartphone, calls up and shows three full pages listing dozens of computer modules for a 2023 Ford F-150 truck.

“A standard car today has about five miles of wiring,” says Stallbaumer, who has 20 years of experience in automotive technology. “Those three pages of modules in the F-150, that’s just computers.”

Because of the complexity of today’s engines, plus the fact that the technology is always changing, training today’s auto techs is a day-to-day exercise. Stallbaumer says he has two master technicians on-site daily who serve as mentors to all the other techs. There is web-based training every quarter, nine categories in which to be certified and three weeklong courses techs have to pass.

Stallbaumer says there also is EV (electric vehicle) training, which consists of 20 web courses in addition to attending a weeklong training seminar in Chicago.

“They’re training all the time,” he says. “In order to be successful in this business, you have to.”

Lopez similarly keeps her technicians up-to-date at Crown Toyota. She has a Service Quality Specialist, Spencer Hutchens, who keeps up with the newest technology and trains the techs accordingly.

“I’ve gone down to the Plano, Texas, (Toyota) campus and attended classes and seminars (on the latest technology),” Hutchens says. “Also, the manufacturer will send module updates. We do specialized training, a combination of online and hands-on training. And I have a direct line to a Toyota engineer.

“I’ve found it’s actually gotten easier for me,” he continues. “It’s almost gotten second nature.”

Eddie O’Dell, senior master technician at Laird Noller Ford, says, “(Learning is) always going on. If you’ve got five years or 25 years, you’re still learning something new every day. I feel like I’m at a point now where I’m dropping stuff I knew in order to pick up current technology that’s put in these vehicles. It’s a challenge, but it’s exciting at the same time.”

counter clockwise from top left: Laird Noller: Zac Carroll, Automotive technician; Rollie Stallbaumer, service manager (on left) inspects engine work; Zac Carroll taking a break from his work; Rollie Stallbaumer, Laird Noller service manager, speaking with a client.

Exciting Time To Be a Tech

Many, if not most, auto technicians will tell you their love of cars began when they were very young. They helped Dad when he was tinkering with the old family jalopy back in the day and fell in love with engines and what made them tick.

Of course, they didn’t know then they’d have to learn such extensive knowledge of computers and the way they work, and most importantly, interconnect with other modules to make all the systems on today’s autos run smoothly and efficiently.

“It’s a difficult job,” says Zac Carroll, automotive technician at Laird Noller Ford, who grew up working with his dad on his cars and started in the business as a lube tech. “Most people look at it from the outside looking in. I really believe (the job is) more thinking than anything.

“I often make the joke that I’m an electrician, not a mechanic,” he says.

O’Dell adds, “I didn’t think we’d ever be where we are today. A vehicle is a computer talking to other computers in a nanosecond so that everything works.”

Carroll says he’s never thought about going back and doing something else as a trade.

“I’ve been a fan of cars since I was a kid,” he says. “It’s different. I’m looking at a lot of kids my age who are in debt from college loans, and they’re not even finished yet and ready to work. I went to community college and instantly went to work.

“If cars are your passion … I work with my hands,” he continues. “I’m able to single my mind on one task at a time. I honestly think I went down the right path.”

It’s not an entirely rosy picture, however. Carroll points out that in a technology class he once attended, he was just one of two who went on to become automotive technicians.

Stallbaumer says the supply of auto techs since the pandemic has tightened considerably. He currently employs nine techs at the Laird Noller Ford operation and says he could comfortably support 12 to 14. That shortage in techs, in addition to equally tight supplies for parts, leads to longer turnaround times for service and frustrated customers.

“We try to be as efficient as we can with what we have,” he says.

LOCAL MATTERS

Our Local Advertisers – Making a Positive Impact

Stallbaumer says he recently spoke to a group of 60 students at a local high school, and only three showed interest in the automotive field.

“Since COVID, it’s changed drastically,” he says. “My opinion is young people today are doing trades, but they’re looking for instant money. In other trades, you can start making money quicker.”

Stallbaumer says he mitigates the tight labor supply by offering starting salaries in the $25- $30-per-hour range with sign-on bonuses, fuel compensation, health care and daycare assistance. He attends career and jobs fairs, and sits on the board at Peaslee Tech.

Although her team at Crown Toyota is fully staffed, Lopez and her team also have had to deal with a post-COVID world where “people are more impatient,” she says.

“We made a commitment to think outside the box to keep the same level of customer service,” she explains. That includes offering more online services as well as sending drivers to pick up and deliver vehicles so that customers can wait from home.

“We wanted people to not avoid service because they were afraid,” Lopez adds.

She’s definitely seen the pool of aspiring auto techs dwindle the last few years. Several decades of the prevailing wisdom being that a four-year college degree can lead to more money is one cause. Car engines becoming so much more complex and technical could be another.

But with the costs of a four-year college education soaring and becoming unattainable for so many, those trends in automotive technician supply could be about to change.

Motoring Forward

“I think the message is getting out there a lot more now,” says Ryan Wingert, assistant service manager at Crown Toyota. “Most trade schools don’t last more than two years. It’s a great jump-start. If you’re comfortable around vehicles, you can learn at a really fast rate. It’s just a matter of putting in the time and showing you’re committed.”

Wingert points out that industry experts say in 10 years, one-third of all vehicles on roads in the U.S. will be all-electric. That typically means less maintenance since there is no oil moving through lines or pistons chugging through cylinders.

Lopez, for one, doesn’t believe that will lead to marked decreases in demand for service. She points out that even during COVID when people left their cars parked and sheltered at home, vehicles were being brought into the Crown garage constantly suffering from “rodent damage.” That’s right. Mice, squirrels and other rodents climbed into engines underneath the bodies of cars and chewed and damaged wiring, and other auto infrastructure.

“People are still going to need service on brakes,” she says. “They’re going to need air filters, tires rotated.

“It’s always changing because of technology. It’s a constant learning environment,” Lopez adds. “But I think the push for trades, including automotive trades, is definitely coming back.”