| story by | |

| photos by | Steven Hertzog |

| OPEN A PDF OF THE ARTICLE |

These Lawrence companies have overcome the challenges through the years and have become iconic staples in the community.

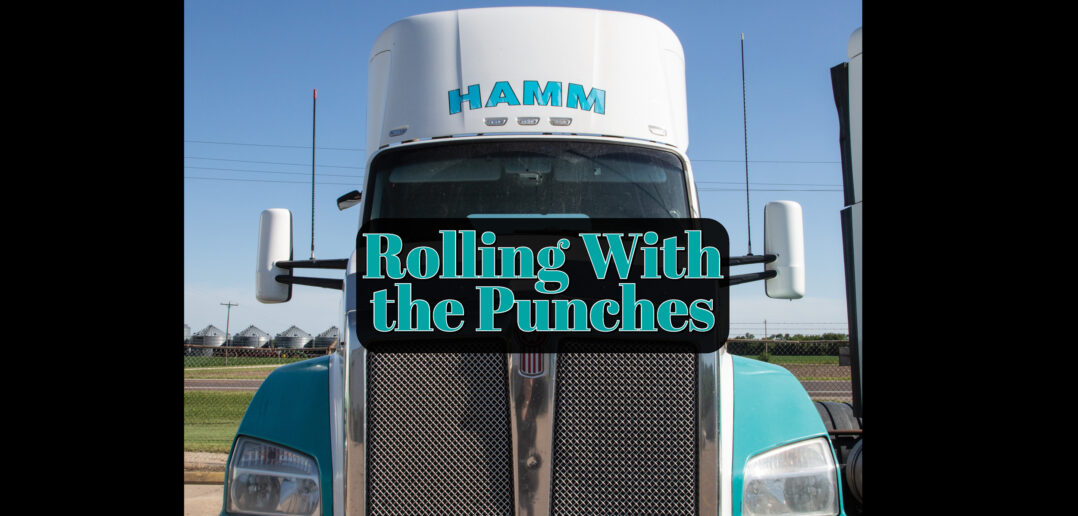

One of many Hamm owned trucks we see daily in Douglas County

The last two years-plus have been an interesting time for businesses all around the world, the Lawrence area not excepted. The worldwide COVID-19 pandemic brought with it unprecedented challenges and obstacles that left countless companies in its wake and out of business.

As a business disruption, however, the pandemic was far from unprecedented. Remember the housing crisis and recession of 2008? Another recession nearly as deep in the 1980s? And don’t forget natural disasters such as the great Kaw River flood of 1951.

Any and all of these historic and notorious occurrences crumbled many a company, including many in Lawrence, which as a preeminent college town already has its share of short-term restaurants and bars shuffling in and out of the picture.

However, there are survivors. Not only survivors but thrivers—companies that have persevered and powered through the downcycles to become iconic staples as long-standing Lawrence companies. Some date back more than 70 years. Most, if not all, have one thing in common: an unwavering ability to be flexible and make necessary changes during changing, and challenging, times. Long-standing businesses can view their existence like a 15-round heavyweight prize fight. During difficult rounds, you either take a punch head-on and get knocked out, or you roll with the punches and live to continue fighting.

The survivors roll with the punches, shifting focus, narrowing business operations and juggling finances as conditions warrant.

HAMM Companies has been in business in its current state since 1954 but actually got its start in the previous decade with an entirely different modus operandi. Kennedy Glass began operating out of what essentially was a two-car garage in 1950, strictly working in auto glass, but today provides not only windshields but windows, shower doors, mirrors, storefronts and all things glass for Lawrence and surrounding areas. ES Lighting incorporated in 1964 in a small tax office at Seventh and Connecticut streets and today continues providing lighting and light fixture solutions to customers throughout the area. And Patchen Electric & Industrial Supply Inc./Pump & Well Drilling Inc. has been selling and repairing electric motors and pumps since 1948.

All of which points to another element each of these veteran companies possess that has enhanced their stability and success: strong familial legacies that have been passed down through several generations.

“I think it’s really cool to have a company with this much historical relevance,” says Stefan Garrison, CEO at Kennedy Glass. “But what’s really great is that we continue to have relevance to this day and continue to grow.”

The same can be said for all four of the long-standing companies—the survivors—mentioned above.

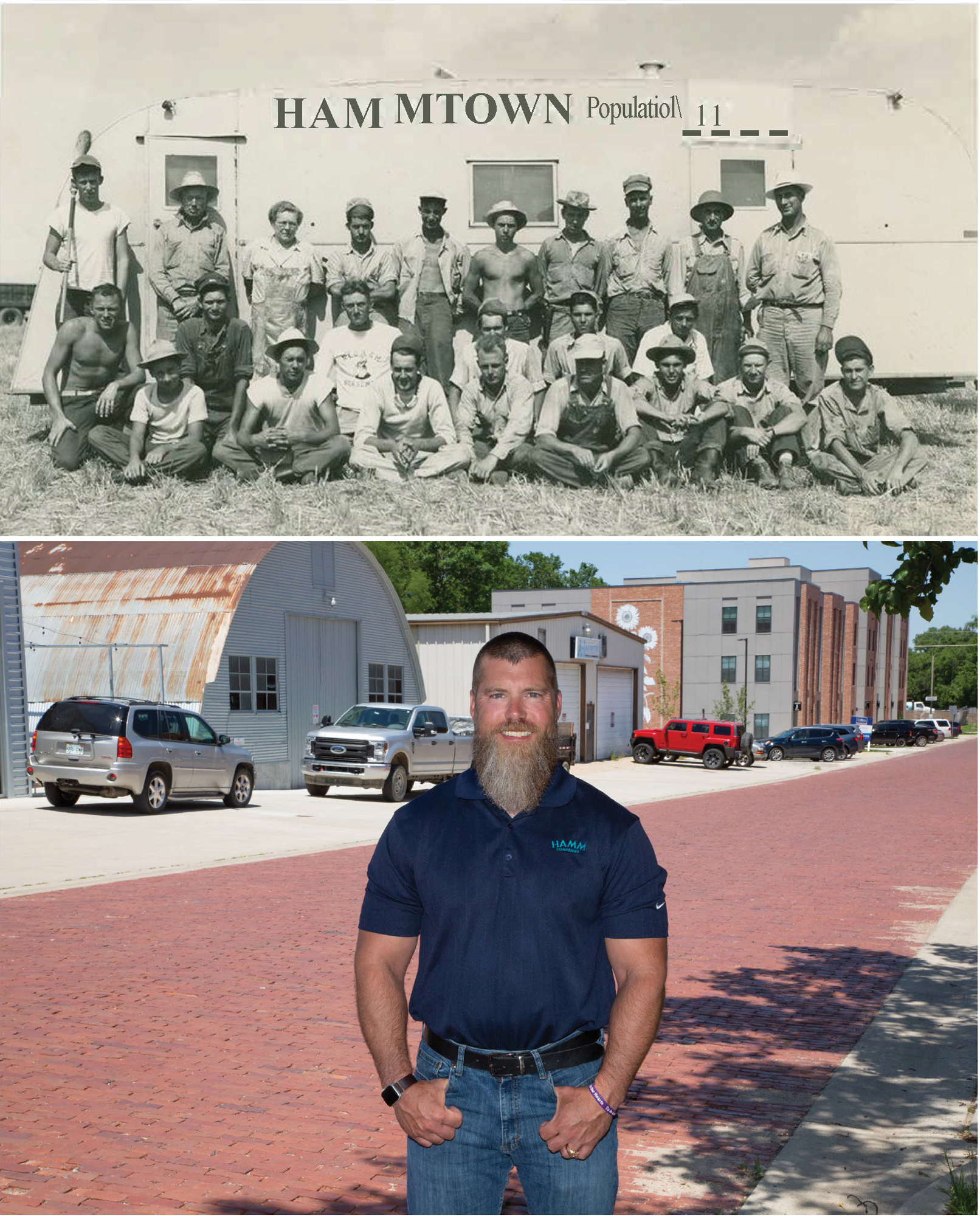

Hammtown, circa 1948. Hammtown is what the travelling custom cutting group was called.; Jeff Hamm, Vice President, ESG of Hamm

HAMMing It Up

HAMM Companies has been involved in everything from supplying aggregates—in most cases limestone—through its quarries, to asphalt, foundation and road work, to waste-management services since forming in 1954. But Norman Hamm actually started his own company back in the 1940s when he put together a custom cutting crew, hiring out to farmers from Canada to Texas harvesting crops.

Norman’s great-grandson, Jeff Hamm, who serves as the company’s vice president of environmental, social and governance, says the transition to construction occurred as a direct result of the ’51 flood. Many of the farmers the Hamm crew cut for had their crops wiped out and fields left unplantable. With ground-moving machinery already in hand, Hamm was hired to bulldoze and plow the fields over.

After that, Norman and his son, Gary, were brought on to help dig out and construct Perry Lake and Clinton Lake, along with other flood-control measures, hoping to ensure such a disaster didn’t again occur.

“They just took that and ran with it,” Hamm says. “They got heavy into highway construction, parking lots, anything horizontal. They then started selling limestone aggregates out of our quarries.”

He says his great-grandfather and grandfather continued the custom cutting business until sometime in the 1960s. In 1981, they started a landfill and began the sanitation and waste-management part of the business, which now includes a state-of-the-art materials recovery facility. A decade later, Hamm Companies purchased an asphalt company out of Topeka.

HAMM joined the Summit Materials group in 2009 but continues to operate as HAMM Companies. Today, the company operates the sanitary landfill northwest of Lawrence and not only serves the city but also surrounding cities such as Olathe.

The company also has been flexible and made adjustments to continue thriving during the pandemic. Back in January, it divested from its asphalt and construction parts of the business to focus primarily on aggregates and waste management.

“One of the main reasons we’ve been so successful is our commitment to safety and the quality of people we have working for us,” Hamm says. “And we’ve been nimble. Whether it’s working on big highway projects or scaling down to smaller work … . My great-grandfather once told me the secret to HAMM is doing it right the first time and focusing on quality and the customer experience.”

HAMM is one of the largest employers in the Lawrence area, employing upwards of 550. However, the company hasn’t been immune to the labor shortage, which has affected business nationwide since COVID. To combat that, the HAMM Foundation is a nonprofit dedicated to cultivating innovation and educational opportunities with the focus on infrastructure and the construction industry.

Eric Vail (President) and Stefan Garrison (CEO); Nick Kennedy removes and replaces a windshield

Smooth as Glass

Kennedy Glass is another venerable company with very strong, generational family ties, and although the Kennedys sold the company two years ago to local developers Tony Krsnich and John Stephenson, there remains a strong Kennedy presence in nearly everything the company touches.

The Kennedy family moved to Lawrence from Joplin in 1950, and young Marty Kennedy joined his father in the glass business when he returned home from the Vietnam War in 1971. He ran the company as its president for decades before the sale but still comes in to work every day as a consultant to the new owners.

“I’m proud they wanted to keep the Kennedy name,” says Kennedy, now 74.

The business, originally located at Ninth and Delaware streets, started strictly in auto glass but expanded to other areas as customers asked for other types of jobs. And it was very much a family affair, with Marty’s mother serving as the company’s bookkeeper for many years. To this day, Marty’s nephew, Nick Kennedy, who’s hung around the glass shops since he was a young boy, oversees the auto glass division.

Now, with 35 employees, 13,000 square feet of shop space and new offices, Kennedy provides customers full service in auto, residential (window repair and new), shower doors, mirrors and commercial work (storefronts). The company delves a bit into selling wholesale products, does some city service work and even has a retail side for door parts, windows, and glass for picture frames and tabletops. It also is able to custom-build vintage glass fixtures used to restore and preserve older homes.

“Pretty much whatever people need,” says Eric Vail, company president.

Kennedy recently revamped a trophy case at the University of Kansas (KU), installed some mirrors at the KU basketball facility and even installed a side of men’s basketball coach Bill Self’s office that, with the flip of a switch, can turn it from a window overlooking the practice court to a whiteboard.

Like other long-standing companies, Kennedy has been able to weather challenging economic periods by being flexible. For instance, one way it made up for lost business during the pandemic was to shift to manufacturing sneeze guards.

“Being flexible allows us to pivot to battle some of those downturns,” CEO Garrison says. “Work picked up last year, but there have been supply issues. Instead of talking about jobs in weeks, it’s now in months. The challenge is to keep quality and safety up to snuff.”

Marty Kennedy, who’s seen it all over the last 50-plus years, has no doubt the company his family built will endure.

“Eric and Stefan have a great rapport and great ability to work these things out,” he says. “We have a great flexibility with the community and involvement with the community. I’m sure we’ll keep doing the same things we’ve been doing but improve. Just like we’ve been doing.”

Grant Lechtenberg, owner of ES Lighting inside his showroom

Lighting Lawrence

Grant Lechtenberg beams when he refers to lighting as “jewelry for the home.”

For the last 20 years, he’s been “dressing up” residences and businesses throughout the city and surrounding areas with creative lighting solutions and fixtures he sells out of ES Lighting’s East Lawrence showroom.

The company was started by Lechtenberg’s grandfather, an electrician and light fixture sales representative, as an electrical wholesale house. In fact, Lechtenberg’s grandparents lived above one of the business’s early locations, at 10th and Vermont. Shortly after Lechtenberg, who’d worked with his father in the company since he was 5, purchased the company, he decided growth was too slow in wholesale, so shifted out of electrical and into lighting. As he puts it, “anything to do with indoor lighting.

“What we really sell are services,” Lechtenberg says. “The art of lighting, lighting design. We inform customers of technologies. There are a lot of options today.”

He says the public’s perception and attitudes toward lighting have changed mightily the last five to 10 years because of the advent of home design TV shows and the internet. That’s led to ES Lighting being flexible and adapting with the changing times, which, in turn, has taught Lechtenberg to be equally nimble in dealing with economic downturns.

Lechtenberg says the pandemic didn’t slow his business; the last three years have been strong. But supply-chain issues, which he says began well before COVID, as well as the labor shortage caused him to begin serving customers one-on-one, by appointment only.

“We spend most of our time chasing down product so we can keep customers on schedule,” he explains. “We’re focused on getting each product done with each customer the best we can.

“We’re adapting the best we can to what’s available,” Lechtenberg continues. “There’s no quick fix to the challenges we face. So we just keep things small and tight like we have been for 58 years.”

ES Lighting has four employees, including Lechtenberg’s sister, Michelle Mailand, showroom manager.

Patchen employees Al & Dan working on a 350 motor for J.M. Smucker

Remaining Essential During Tough Times

Tom Patchen started Patchen Electrical & Industrial Supply Inc. in 1948 across the street from its current location at New Jersey and 9th streets. The company began as a repair shop for electric motors and pumps of all sizes and for all uses. Later, it expanded into sales of electric motors and parts. More recently, it expanded its business to include repairs and parts for water wells and pumps.

Today, the company employs six.

David Patchen, grandson of the company’s founder who runs it with his father, also Tom, says the company has never had to shut down because of economic downturns, natural disasters, recessions or pandemics. It’s too essential, he says.

“We’ve never had to shut down, even one day,” he explains. “We sell critical parts to machinery used to run hospitals and things like that.”

Patchen sells parts for and repairs things from as small as a motor in a typical residential air-conditioner to large, industrial-sized air-conditioners. If you’re in need of a part or repair on a working piece of machinery, chances are Patchen has a solution, from water well drilling and pump service, to transmission service, to dynamic balancing of rotors, impellers and blowers, to hose fabrication and assemblies, to services of drive belts and chains.

The company offers emergency repair service in the shop or on-site 24/7 and same-day or next-day delivery of parts.

Supply-chain issues have come into play recently, especially for special builds, which can take up to four to five months to get in parts, Patchen says. And prices have spiked upward in just about everything the company does. Otherwise, he says it’s business as usual at Patchen. In fact, he says business has been steady as ever.

“We try different things sometimes to keep the business going,” Patchen says. “We’re just here every day and work it out from there.”