| story by | |

| photos by | Steven Hertzog |

| OPEN A PDF OF THE ARTICLE |

Baldwin businesses involving machinery continue to thrive even through the COVID pandemic because the need has remained steady.

Hey Machinery

Baldwin City’s handful of industrial-based businesses share a commonality that would make Archie Bunker smile.

When it comes to owning and operating companies that make, sell and/or service large machinery— mostly used for agricultural purposes in this part of the country—it appears to be all in the family.

Hey Machinery

Hey Machinery Co. Inc. was founded by William Hey in 1929 and today is owned and run by his great-grandson and fourth-generation proprietor Brian Hey. While Bryan Rice might be the first-gen owner of Rice Precision Manufacturing over the 22 years of the company’s existence, just about every member of his immediate family has played a hand in its operation and successes. Same can be said for Custom Mobile Equipment Inc., which was started 28 years ago by Gary Dick and today includes several family members among his 30 employees. And while Heritage Tractor has exploded into its own conglomerate, expanding to 21 locations in three states, the company started near the turn of the century as the family-owned business of Ken Wagner.

“I started working summers here when I was 14 or 15 years old,” Brian Hey says. “I’ve always been interested in the business. If you grew up in our family, that’s just the way it was.”

The four Baldwin City industrial businesses have something else in common. They all appear to have come through the COVID-19 pandemic just fine, if not better than ever. Though the pandemic interrupted great swathes of the U.S. and world economies, the world moved on and needed machinery, both heavy and small, to do so.

“Our business is as good as ever,” Bryan Rice says. “The sky’s the limit. It’s just up to what we want to do as a group. We want to be the very best. We have to believe and execute that we can make the best quality parts at the best price when the customer needs it.

“That’s what we’ve done, and it just keeps going, going and going.”

Hey Machinery, Custom Mobile Equipment and Heritage Tractor also strive to be the best in their fields and regions, and as the country begins its recovery from COVID, each seems poised to be as good as ever.

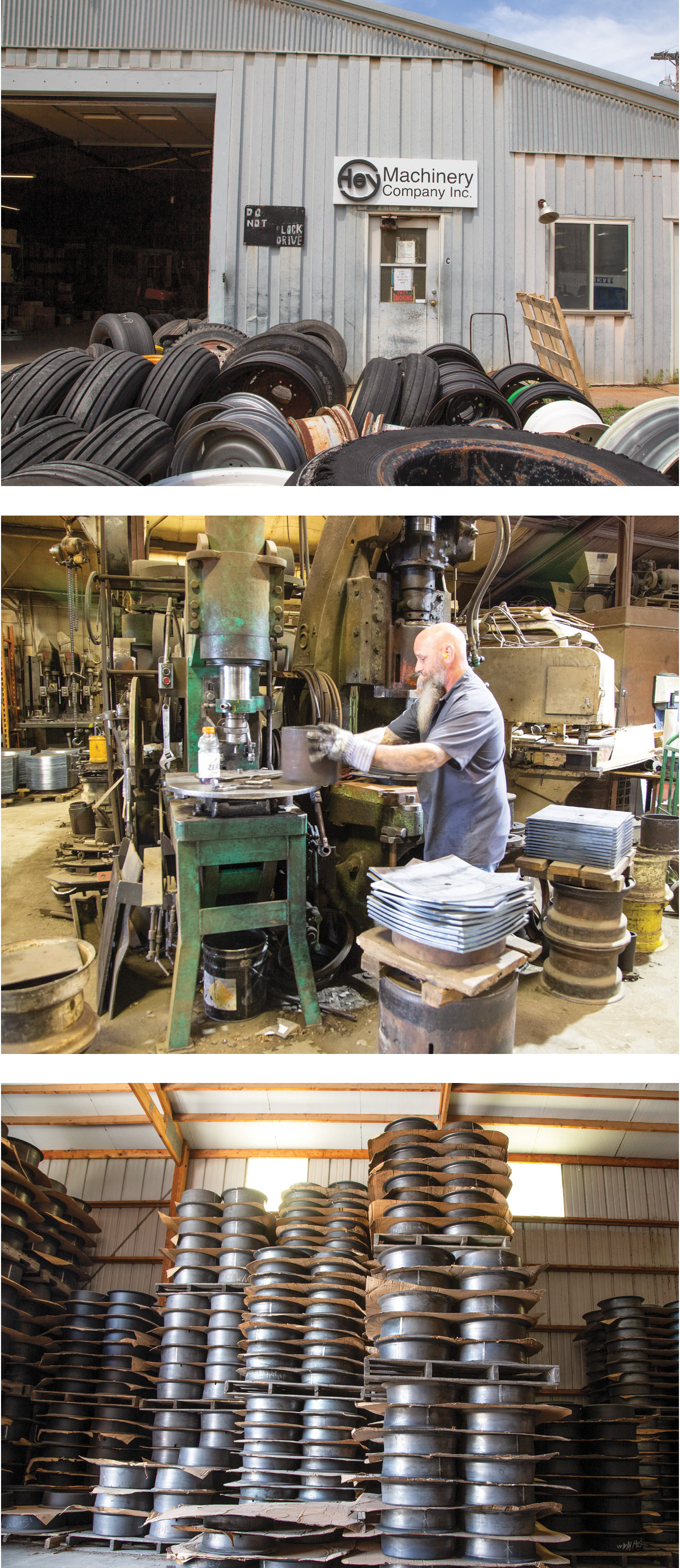

Hey Machinery

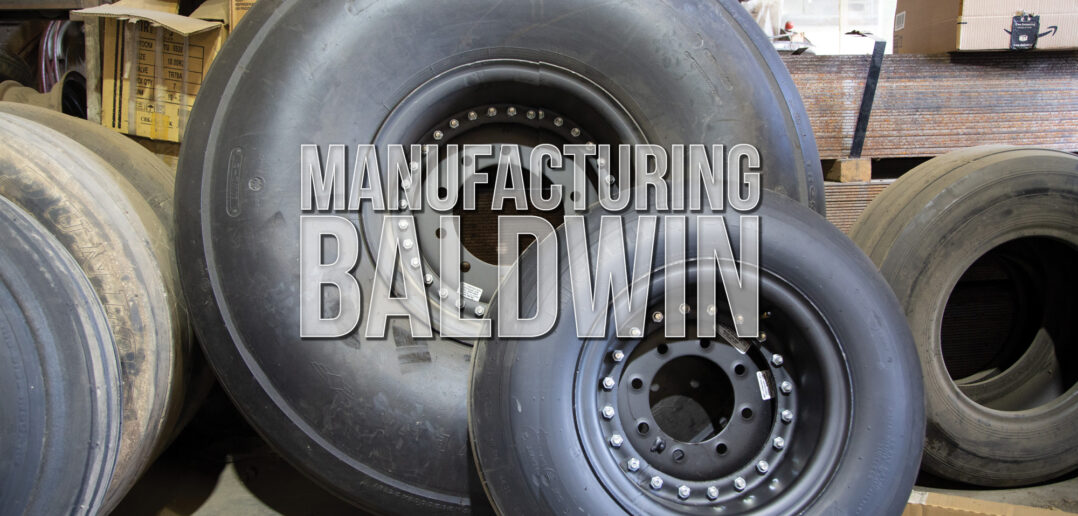

Hey Machinery, which often goes by the more accurately descriptive name of Hey Wheel, has been manufacturing and reselling wheels, rims, centers, tires and other off-highway products since 1929, when the company was started by William Hey. Hey was soon joined in the business by his sons, Bill and Lester, and the company has remained in the family through four generations.

In its early years, Hey Machinery did many different things, but William quickly found that producing wheels that worked with used or rejected aircraft tires was profitable when sold for farm use.

Specifically, the company manufactures what’s known as a “bolt-together” wheel, a two-piece wheel fastened together by anywhere from 20 to 32 bolts. These sturdy rims can be used to anchor disregarded-yet-heavy-duty airplane tires and used for feed wagons, grain carts, manure spreaders, tractor fronts, brush mowers, scrapers, skid loaders and other uses.

The company sells its bolt-together wheels to original equipment manufacturers (OEMs) and distributors, and directly to customers in need of sturdy tire solutions for harsh environments and heavy-duty applications. Business is steady, Hey says.

“Everything we do is for farming, agriculture vehicles,” he continues. “Probably 80 percent of what we do gets shipped out the door.

“Thirty years ago, we started selling tractor and implement wheels,” Hey adds. “But we don’t make them, we just sell them.”

Baldwin City has undergone many changes and much growth over the years, and Hey says nothing speaks more loudly to that fact than when he gets approached by someone who has no idea what or where Hey Machinery is.

“Baldwin has grown,” he says. “It used to be everyone knew who and where we were. But now, so many people have moved in who didn’t grow up here, there are a lot who don’t know us.”

That’s OK, he says, as long as farmers keep needing wheels and tires.

Rice Precision Manufacturing

Brian Rice, owner/operator pf Rice Precision Manufacturing

Rice Precision Manufacturing was established by Bryan Rice as sole proprietor in 1999. Today, the company employs 23 full time inside a 14,000-square-foot facility that specializes in precision machining of various materials as well as welding and fabrication of assemblies large and small.

In simpler terms, it creates parts for large machinery.

Rice Precision engages in a wide variety of services that include new part and assembly design, welding and fabrication, and reverse engineering, which allows it to quickly and efficiently produce replacement parts at pricing that is more competitive than typical OEM suppliers.

“We work with clients that need to outsource their manufacturing needs,” Rice says. “We deal mostly in single parts but some assembly, as well.”

Rice says his clientele is very diverse, but much of the parts the company manufactures and sells goes to the food industry.

“Schwan’s has a facility in Oklahoma that makes pies,” he says. “The machinery used to make those pies have parts made by Precision.”

Rice says the company also deals heavily in the oil and gas industry, and is looking at getting into the medical field.

Being headquartered in the Baldwin City area has had its advantages and disadvantages, he explains. The city welcomed the company with open arms 22 years ago and has remained a good partner since. However, finding employees can be challenging.

“A disadvantage definitely is a limited labor pool,” Rice says. “There are no classes in high school that teach this anymore. We try to recruit from our area. A lot of kids around here work on their own cars.

“If I can just get them through the door, I can show them what we do, show them there’s an avenue here for them where they can make $30 an hour.”

And Rice Precision is very much a family-run business. Bryan’s wife, Cheryl, is the company’s chief financial officer. Brother Duane is its head of procurement. And daughter Bailey also is a full-time employee.

Custom Mobile Equipment Inc.

Custom Mobile Equipment Inc.

Custom Mobile Equipment Inc.

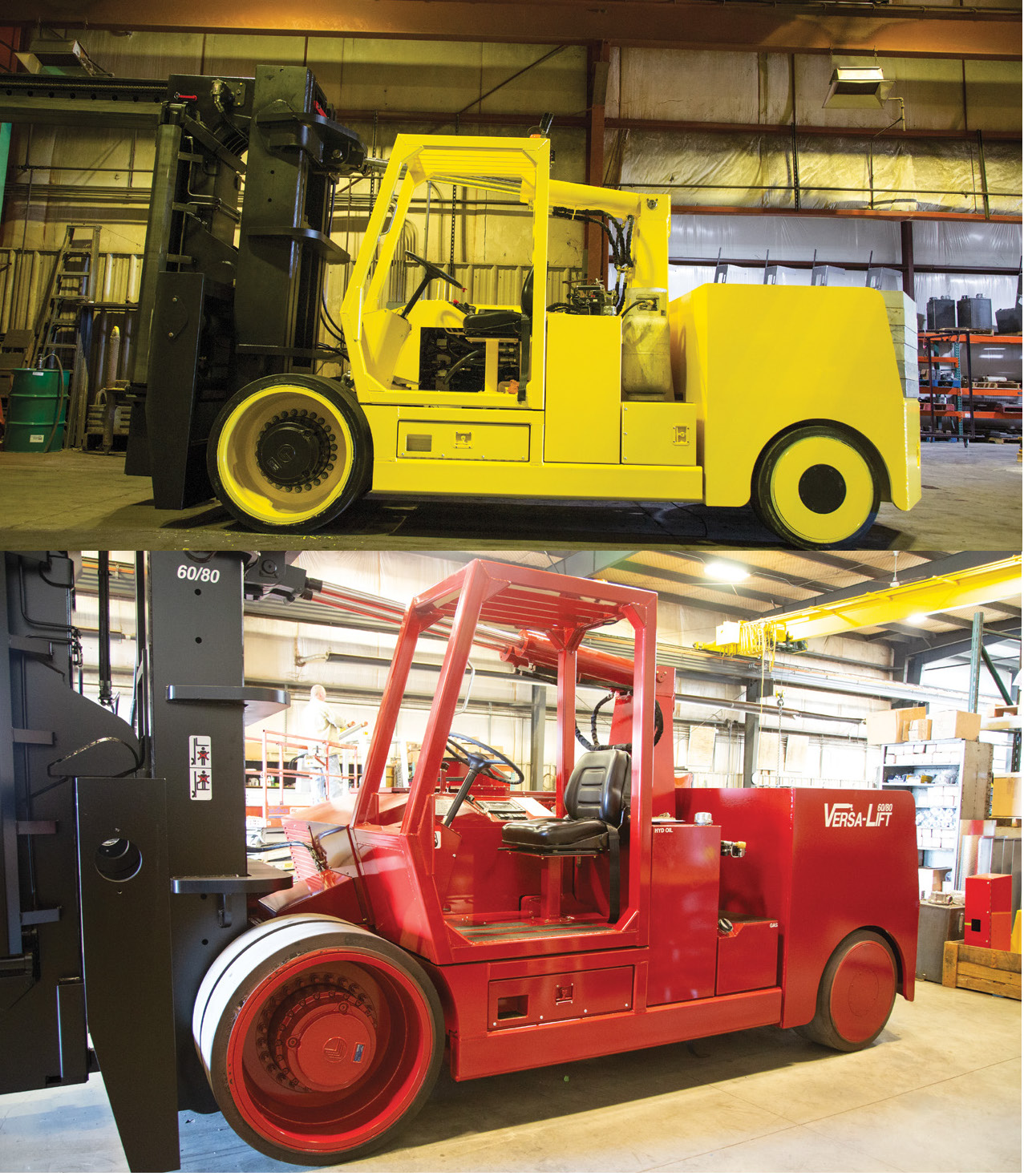

Back in 1993, Gary Dick had an acquaintance who lived in Coffeyville, Kansas, who was unhappy with the bulky forklifts he was using and wanted a more smoothly operating specialty fork lift for his business. Dick designed and produced that fork lift for his friend, Jim Taylor, and soon after, started fielding requests to custom-build more forklifts, especially for machinery-moving contractors.

Dick trademarked his creation, the Versa-Lift, and Custom Mobile Equipment Inc. was born. The Versa-Lift is a unique forklift in which the frame extends to achieve greater capacities and is equipped with a removable hydraulic boom. It is designed specifically for moving heavy machinery smoothly and safely on solid surfaces.

What started in ’94 in a small, rented space in east Lawrence today is a 60- x 100-foot, 40,000-square-foot building on 4 acres in a Baldwin City industrial park.

“We outgrew our space (in Lawrence) and moved to Baldwin City in ’97,” Dick says.

Today, Custom Mobile employs 30, an increase from just Dick and two part-time helpers when the business started. Over the years, Dick and his team have upgraded and built larger Versa-Lifts so that now, the company sells seven models, including two electric-powered, in five sizes, with the largest having a 140,000-pound load capacity.

On average, Custom Mobile builds between 80 and 90 built-to-order Versa-Lifts a year and ships them all over the world, including to South Africa, Europe, South Korea and China.

“Demand has stayed steady through COVID,” Dick says. “The future looks good. I don’t see any problems on the horizon.”

And yes, Custom Mobile sources some of its parts for its Versa-Lifts through Rice Precision.

“It’s good to have a machine shop nearby,” he says.

Like his peers at Rice, Dick’s business also is a family affair. Gary’s son, Nathan, has been working with his dad since getting out of college and handles sales. Brother Greg runs the shop. Another brother, Keith, has been the company’s longest-running employee. And a nephew, McKinley, handles purchasing.

Heritage Tractor

Heritage Tractor

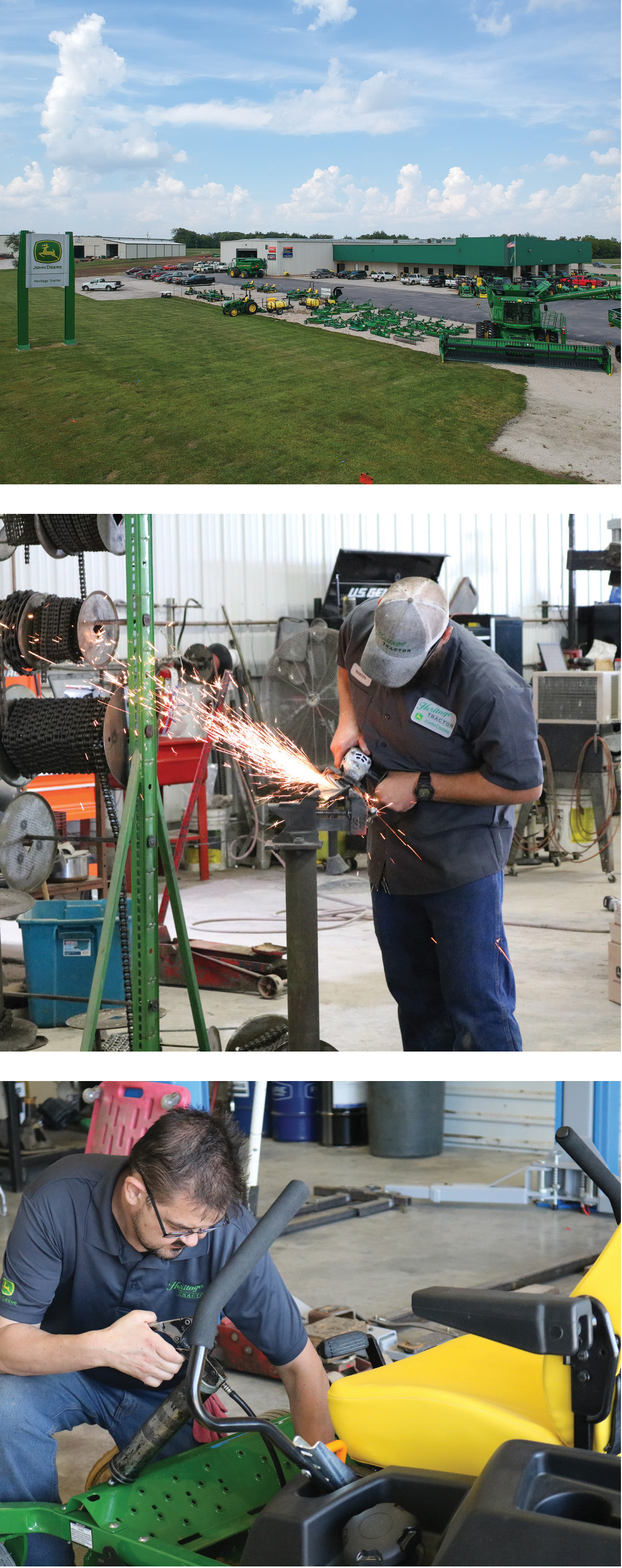

Heritage Tractor isn’t recognizable today from its humble beginnings near the end of the 20th century.

An uptick in agricultural equipment sales in the late 1990s led tractor-producing titan John Deere to seek to add a new dealership somewhere in the fertile rural ag market of northeast Kansas, close enough to also tap into the Kansas City marketplace. Baldwin City was selected as the location, and Ken Wagner was approached for advice and leadership on the project. He jumped in with both feet as owner of the original facility, which sits on a 17-acre property just outside town.

Leap forward to today, and Heritage Tractor has 21 locations in Arkansas, Kansas and Missouri. But Baldwin City is still the company’s hub.

“It was decided there was a need for a dealership with agricultural ties for Baldwin City and surrounding cities,” says Jessi Ganoung, marketing manager. “From there, Heritage either bought or acquired other dealerships.”

Ganoung says there are three major components to Heritage’s business: sales, parts and service, with the bulk of business going to the latter two.

“We’re very appreciative of farmers who keep food on our tables,” she says.

In addition to tractors, combines and other large implements, Heritage sells small mowers, both residential and turf lines, walk-behinds and stand-ons. Also, small, commercial construction equipment like skid steers and mini excavators, as well as Stihl chainsaws, trimmers and blowers, and Honda push mowers and generators.

It also sells all-terrain vehicles most commonly known as “Gators” for farmers and municipalities.

Include Heritage Tractor as a Baldwin City-based industrial business that was not affected by the global COVID pandemic.

“This time last year, we were holding our breath,” Ganoung says. “But (an economic downturn) never happened. New homes are going up every day, breaking new ground. When customers move into those homes, they need to buy mowers to mow their yards.

“It never slowed down. We’ve been proactive in keeping our inventory up.”

Though Heritage Tractor dealerships now can be found throughout a three-state area, the company never forgets where it all started.

“Baldwin is a leader of the pack,” Ganoung says. “We do a lot of parts business, and the service is close behind.”

![]()