HEAD:

by Darin M. White, photos by Steven Hertzog

| story by | |

| photos by | Steven Hertzog |

| OPEN A PDF OF THE ARTICLE |

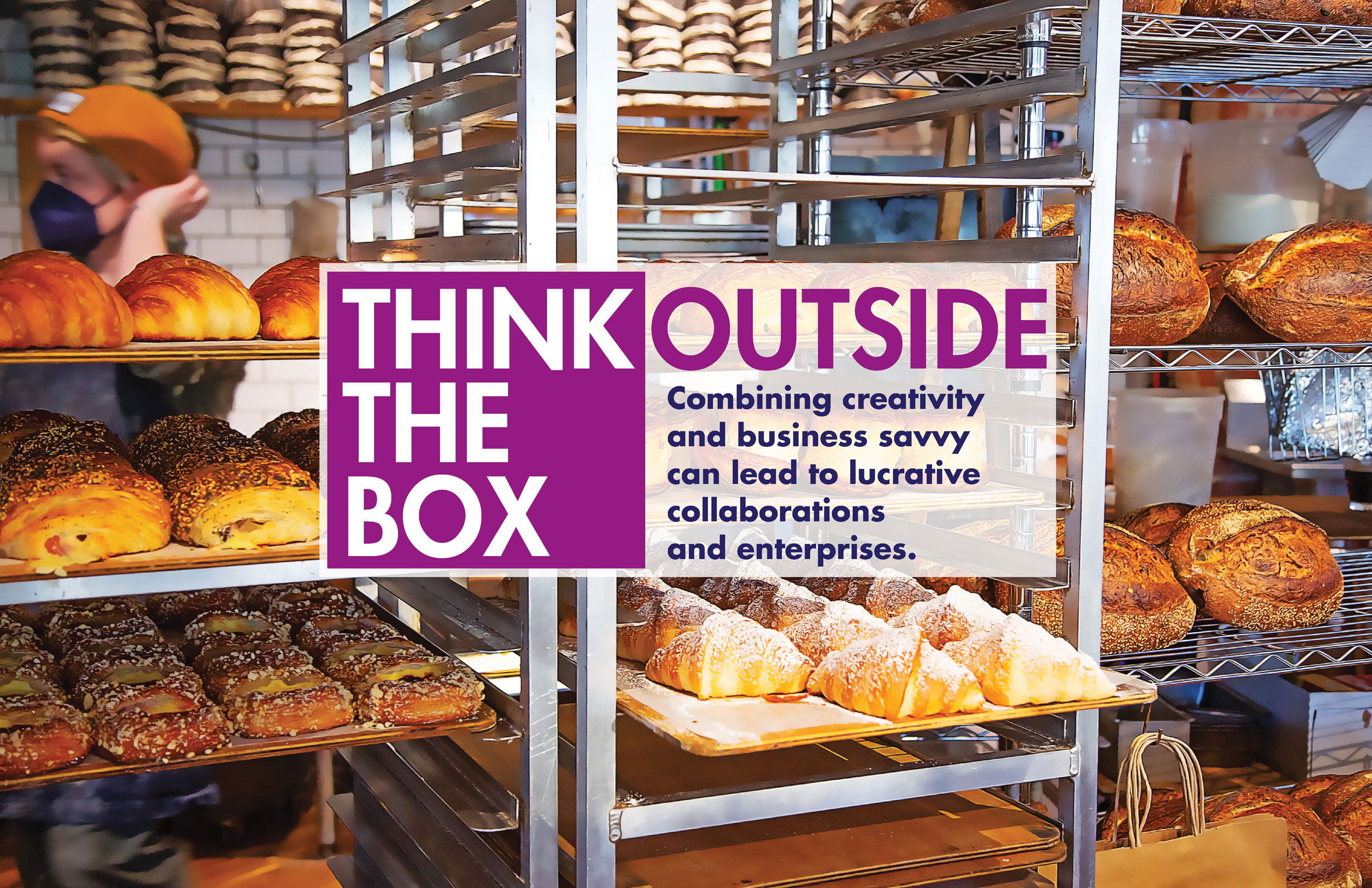

Combining creativity and business savvy can lead to lucrative collaborations and enterprises.

1900 Barker, racks of freshly made pastry

One of the most beautiful things about the city of Lawrence is that the world has come to us. This is second best to actually traveling to those other nations. As Mark Twain wrote, “Travel is fatal to prejudice, bigotry and narrow-mindedness, and many of our people need it sorely on these accounts.” As a local, even if you struggle with the influx of thousands of students every fall, the University of Kansas (KU) draws many of these students from countries all around the world. With this convergence of nationalities comes an influence of other cultures, including different, if not creative, ways of thinking, living and, of course, eating.

I close my eyes, I am in Paris, France, with my wife, Shannon, when I have the opportunity to not only show my artwork but curate the hanging of the work in the basement of a converted convent-turned smoke-stained discotheque-turned gallery. In my memory, I jaywalk across the street diagonally just off Rue de Rivoli and enter the café. I order the pastry and espresso, and sit at a table looking out onto the freshly rain-dampened street. I bite into the pastry, the delicate flakey layers crunching, covering myself in the bits of pixie dust and savoring the flavors, only to open my eyes and realize that I am actually in the 1900 Barker Bakery and Cafe, in Lawrence, Kansas. Owner, pastry chef and baker, Taylor Petrehn, is a four-time semifinalist for Outstanding Baker in the prestigious James Beard Foundation awards. In James Beard’s words, “Good bread is the most fundamentally satisfying of all foods; and good bread with fresh butter, the greatest of feasts.”

Prior to opening the bakery, Petrehn was a pastry chef in Kansas City and making bread as a hobby in his Lawrence home basement to give to friends and family. The inspiration for the location was the idea of an old school-corner café and bakery off the beaten path that neighbors in the vicinity would be drawn to for well-made pastries, bread and good coffee. Petrehn and his brother, Reagan Petrehn, opened the location at the corner of 1900 Barker St. in 2015 out of an abandoned laundromat.

At 1900 Barker, baker Alex Martin rolling the dough, and serving customers at the counter

The once-dull interior has been transformed into a contemporary space complete with exposed rough wood rafters, clean cast cement countertops, a display case with pastries, an open kitchen and café, and extensive patio seating. 1900 Barker Bakery and Cafe is appropriately named as it sits on the corner of a roundabout on highly traveled 19th and Barker streets, in the middle of a residential area. It has quickly become a staple not only for the neighborhood but also for the city and surrounding communities.

Baking is not for the laissez-faire, where creating a loaf of bread can be a 30-hour process. “Baking is a super-repetitive, detail-oriented process,” Taylor explains. “This draws people who enjoy the details. The better you understand the process, the more creative you can be.”

One of the joys, and something he is proud of, is seeing the development of the people he trains. The next phase for Taylor is an expansion to another laundromat at 19th and Louisiana streets, which will become a “bespoke donut shop with an emphasis on seasonality and local ingredients,” as well as off-sight baking manufacturing for 1900 Barker.

Lawrence is no stranger to fantastic breads and pastries, much to our citizens’ delight. We welcome a newcomer to this list: Cellar Door Café, at Seven E. 11th St., in Downtown Lawrence, which launched in June 2020. Despite being the new kid on the block, owner Louis Wigen-Toccalino has been part of the Lawrence business scene for eight years, formerly the owner of East Lawrence coffee shop Decade.

Despite the plethora of challenges, he believes the “COVID era is an opportunity to define what is successful and what is not. Customers might be a little more understanding during this time,” he says.

Wigen-Toccalino is interested in building a new model of restaurant that is sustainable for workers, including the ability to learn a craft, set wages, enjoy paid time off and raises with more stability. This is a chance to maintain a team for the long term, which will help with the cost of training, the level of quality and overall staff turnover, which is so prevalent in the service industry.

Manufacturing is very much a part of the café. It is a “zen” daily process of starting early, having an assembly line to create the eatables, selling the day’s work, cleaning up and getting prepared to replenish the goods again the next day. He likes the routine of the work and the problem-solving aspects of developing a recipe. He also enjoys the creative process and cooks like a baker, creating new recipes until they are perfected and easily replicated. Cellar Door offers a wide variety of coffee drinks, lunch plates and bistro, and bakery pastries.

top to bottom: Ryder Werts hand pouring column candles; Owner’s Bob and Deb Werts in the Waxman retail showroom; Bob overdipping a ball candle for carving; Ryder working on taper candles

A Local Treasure

At the other end of Downtown Lawrence, Waxman Candles continues to craft its handmade candles and, more recently, expanded to producing ceramics and glassworks. Waxman has been a fixture in this community since 1971.

Craftsman Bob Werts’ interest in candles started while he was a student at Dodge City Community College. A friend invited him to make candles with a group for fun, and he enjoyed the process. He found that others appreciated his work, and he traded candles for wax. While a student at KU, Werts started Waxman Candles out of his apartment on Tennessee Street in 1970 and opened the store on 14th Street in 1971.

Werts has credited the longevity and success of the store to having a hard head by believing in himself, working hard and trusting his instincts. He also surrounds himself with the right people, not only to work with but to bounce ideas off of, and he allows himself time away to rejuvenate. Nowadays, a number of these “right people” are his family. Daughter, Melanie, son Ryder, and wife, Deb, work at the Lawrence location, while son Mitchell runs the Chicago location. He also credits a fabulous staff that currently works there and those who have been a part of Waxman over the years. The team members become part of the family, and they are treated as such. Werts is grateful to Lawrence residents who have not only supported Waxman Candles but have introduced visitors and friends to the store.

Production manufacturing started very early in the business, as a perfume company from Kansas City asked Werts to make 120,000 candles. After seeing his space and realizing all of his candles were handmade, company leaders were uncertain that he could do the work, but he assured them he could do it. The perfume company gave him a chance, and this was the first of a number of large orders Werts produced for this company.

Waxman has collaborated with local businesses such as Grandstand Glassware & Apparel and Bracker’s Ceramics. Grandstand produces printed glassware for Waxman candles and beer candles. Waxman provides chocolate candles, beer candles and other seasonal or requested scents that Grandstand offers in printed glassware for its clientele. When Werts saw the need, Waxman began to produce its own line of ceramics and slumped glass. They worked with Bracker’s to get kilns set up and are now producing not only candle holders and candleware items, but also a line of dinnerware. All the work is handmade and made well.

Blue Collar Press Ink wall; top to bottom: Custom mixed colors sorted by Pantone number; Blue Collar Press and Merchtable owners Jim David and Sean Ingram; Blue Collar Press production floor. Printer setting up to restart automatic t-shirt press; Screen tech prepping screen to remove emulsion and reclaim screen for reuse.

Made in Lawrence

On the southeast side of Pine Ridge Plaza, in South Lawrence, Blue Collar Press provides production for screen printing, embroidery, finishing, tour supplies, promotional merchandise and more while sister company, Merchtable, offers an online retail software platform and fulfillment. They are not only proud that their products are made in Lawrence but have expanded to work all over the world with major music bands, record labels and more.

Blue Collar Press was launched out of co-owner Sean Ingram’s basement. His metalcore band, Coalesce, had a felt need: more calories. To eat more burgers while the band was on the road, they needed more money. Ingram started printing his own T-shirts, which allowed the band to make and keep more funds, and take care of those needs. During the process, Ingram saw an opportunity to not only print merchandise for his band but also make goods for other bands.

Not far away at about the same time, Jim David’s band, The Anniversary, needed merch for its shows. So he began printing T-shirts out of his basement. He realized he would need someone to help keep up production while the band was on tour. He hired Ingram to provide the band merchandise. Shortly after, David joined Ingram as co-owner at Blue Collar Press, and they combined forces to meet the growing demand. These changes and growth (that have expanded the company to 30) “have happened organically, making products, as needed, to expand our production and distribution,” David remarks.

With demand, the business eventually changed from a “distribution company that put things into a box to a distribution company that offered creative solutions,” David explains. For example, helping bands order the correct quantities of merchandise needed to fill the demand was necessary. The problem-solving solution, in this case, was to “apply logic to create a spreadsheet,” Ingram says, which would allow each band to more accurately estimate the merch needed for upcoming shows. “Creativity is in the communication,” Ingram says.

Creative solutions also rely on flexibility and adjusting to industry shifts. A major shift was the meeting of two industries—promotional items and normal band merchandise—when artists need better-quality promotional goods to sell. Blue Collar Press saw this as an opportunity to help with sourcing and providing promo goods, and also assist with unique “passion projects” for the band.

At one point, record labels began burdening band managers and requiring more of their funds and time. The managers, in turn, asked Blue Collar Press to take more responsibility and solve more of the problems, including merchandise marketing and promotion, providing samples to other bands and delivering to shows among other things. To understand how to take on these challenges, Blue Collar asked a potential client what friction points he or she had with a previous company, a litmus test to examine what types of issues needed to be addressed. “Problem-solving is the heart of creativity,” Ingram suggests.

Lawrence Paper Company design manager Mike Cordaro; May Tveit – Photo Courtesy of the Artist

The Cardboard Effect

While Lawrence Paper Co.’s (LPC) longevity and connection to the City of Lawrence is impressive, when you think of a cardboard box, you don’t initially think of creativity. However, as Blue Collar’s Ingram believes, solving customer challenges requires creativity, and LPC certainly has met this issue head-on. I had the pleasure of seeing a real-world example of LPC’s work when on a tour of Blue Collar Press. As Ingram explained some issues he was having with damage in a shipment of a combination of a vinyl record and a T-shirt, LPC came up with a simple design that solved the issue quickly and cost-effectively.

Not only does LPC provide creative solutions for local companies such as Blue Collar Press, it does packaging, international supply chain, in-store marketing and industrial packaging for businesses from mom-and-pop shops to multinational companies. For a number of years, LPC has developed a relationship with the University of Kansas. It has worked with the Industrial Design program at KU to provide tours of the production facility. The company also provides in-house designers to give feedback on school projects or allows the designers and students to work in tandem on LPC-sponsored programs, which could be considered design blitz projects that “provide real-world applications,” says LPC design manager, Mike Cordaro. LPC has accepted interns from the college, and some, in turn, have been hired on full time.

KU Industrial Design professor May Tveit has worked with LPC in collaborations through her Materials and Processes class. One project is a flat pack lighting design that combines the use of corrugate material and cooperation to design a light that disassembles into packaging. Tveit has not only worked with LPC as a university professor but as a fine artist. Cordaro and team appreciate that “[May Tveit] looks at things with a different set of eyes … we are designing for function … and mass production … and she is designing for art.” Tveit agrees. “I approach the material from a conceptual point of view” and am inspired by “the origin of the box … the box can serve as a metaphor to self.” This thinking about “the geometry of boxes in their unused state” is where her wall series “Universal Boxes,” displayed at the Nerman Museum of Contemporary Art in 2017-2018, emerged from layered laminations to create “topographies.” Both Tveit and Cordaro agree this collaboration is mutually beneficial, as it provides LPC an alternative approach and viewpoint from where to draw ideas and Tveit access to materials, processes and equipment that she would not otherwise have.

Thinking outside (or inside) the box has vast benefits for not only the companies and those associated with them by providing opportunities and jobs for our community, but also for the customers that these industries supply. Creativity and innovative thinking are an absolute necessity to breaking any hardened mold or stereotype, and expanding past the confines of whatever is currently embraced. We can hope that companies will include more creatives and unique thinking in the future. Creatives may not see the same way as others do, which is exactly why this way of thinking needs to be appreciated, encouraged and further explored.

![]()