| 2014 Q4 | story by ANNE BROCKHOFF |

Today’s supermarket meat case is filled with promises. From organic, hormone-free and Kosher to branded and breed-specific, there’s a product for every market niche. While consumers appear willing to pay extra for these, they also want something in return—a guarantee that they’re getting what’s touted on the label.

Stores often emphasize selection criteria and relationships with farmers in attempt to provide that. However, proving the meat in the package came from animals produced on a specific farm or in a particular way can be challenging.

That’s where IdentiGEN comes in. The Dublin-based company, which houses its North American headquarters in Lawrence, uses DNA technology to trace meat through the supply chain. That enables its customers, mostly food retailers and processors, to ensure authenticity.

“We provide a way of assuring the product you purchase is the product you intended to purchase,” said Greg Peters, IdentiGEN’s North American Director of Technical Accounts. “DNA is the barcode that never goes away.”

University researchers have long studied how DNA technology can benefit the food industry. IdentiGEN itself was founded in 1996 by scientists at Dublin’s Trinity College, who were exploring ways to use genetic technology to improve meat safety. While IdentiGEN’s main product, called DNA TraceBack®, undoubtedly plays a food safety role, it does much more than that, Peters said.

The system can be used with beef, pork, poultry, lamb, goat, fish and other protein-based foods. It allows IdentiGEN’s clients to trace individuals throughout the entire processing, packaging and sales process. Clients can then compile information on any trait they care to track, from breed and production method to commercial traits, such as tenderness and flavor.

That’s because DNA TraceBack® uses an animal’s own DNA, or deoxyribonucleic acid, to create what IdentiGEN calls an accurate, permanent and tamper-proof identification tool. Animals are raised just as they otherwise would have been, and then trained workers collect samples from each at the point of harvest, a point at which all identity is typically lost when ear tags and other markers are separated from the carcass.

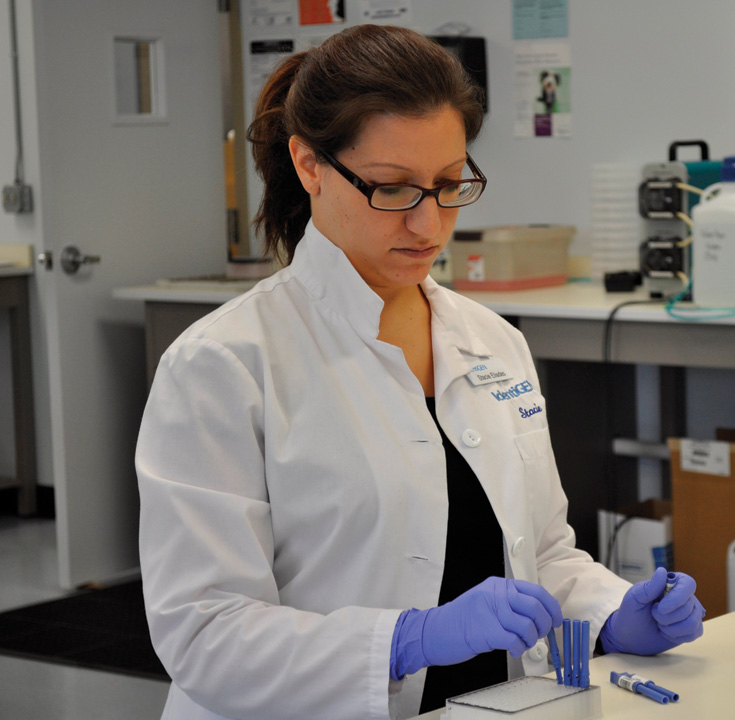

Samples are sent to IdentiGEN’s Lawrence laboratory, where DNA profiles are created. The company also has labs in Dublin, Calgary and the U.K.

Peters declined to provide details about IdentiGEN’s proprietary process, but the company’s website describes it as assessing a panel of genetic markers, technically known as single nucleotide polymorphisms, or SNPs, using what’s called high-throughput DNA analysis.

Genetic profiles of each animal are then created and linked to its production and processing history. Samples are stored for comparison in future testing, which can take place at any point in the supply chain. This means whole cuts of meat, as well as ground meat and even cooked steaks, can be tested and compared to the original sample to verify the meat’s origin.

Should the samples reveal a problem in the system, IdentiGEN’s clients then have specific information to use in correcting it. More typically, Peters said, clients use the data to improve product quality while reassuring consumers the products they’re buying are what they expect.

“Consumers want to know their suppliers,” Peters said. “We’re one of the few companies out there that can complete the chain.”

Growth has been steady for IdentiGEN, which is funded by a combination of retained earnings and venture capital. U.S. clients include FPL Food, the Southeast’s biggest privately held vertically integrated beef processor, Illinois-based Aurora Angus Beef; and Braveheart Black Angus Beef, a division of Performance Food Group Company.

IdentiGEN has just under 100 employees worldwide, Peters said, including 15 to 20 in Lawrence. The total count varies seasonally, depending on clients’ production schedules. Local lab employees typically hold four-year degrees in biology, biochemistry or related sciences.

Many of those are recruited from the University of Kansas, although Lawrence has proven to be a good fit in other ways too, Peters said. When IdentiGEN decided to open a North American office, it had several criteria: the location needed to be in the agricultural heartland, close to a major airport and near a large university.

“We looked in Lincoln, Manhattan, Dallas and all around the area. Lawrence was the best fit,” said Peters, who grew up on a Nebraska cattle ranch and worked for a biotech start-up, as well as for National Beef Packing Company before joining IdentiGEN earlier this year. He holds a Bachelor of Science degree in animal science with a minor in genetics from the University of Nebraska-Lincoln, and a master’s degree in animal genetics, as well as an M.B.A. in finance from Texas A&M University.

The region also has a robust technology climate, thanks to the presence of entities like KU and the Olathe-based Kansas Bioscience Authority, a venture capital organization dedicated to accelerating growth in the state’s bioscience sector.

“The people here are obviously tech savvy and are very comfortable with advancing technology,” Peters said.

IdentiGEN’s Lawrence operation is housed in a low, red brick building on Quail Crest Drive and includes 6,000 square-feet of office and lab space. The company also has off-site storage for both frozen and dry samples. The lab received the U.S. Department of Agriculture’s Process Verified Program (PVP) approval in 2007 in recognition of its lab practices. In 2012, it achieved ISO/IEC 17025:2005 accreditations.

“We are a high-throughput genotyping lab primarily involved in testing for DNA TraceBack®, breed and parentage,” said Stacie Eliades-Becker, Manager of Genotyping Operations for IdentiGEN’s Lawrence facility. “This involves the use of a variety of molecular biology-based techniques and instrumentation.”

The lab operates a single shift, which so far meets the needs of its current client base, Peters said. Should IdentiGEN need to expand in the future, it would do so by adding additional shifts, he said.

IdentiGEN also continues to develop new technologies, including IdentiSNP (patent pending). The product uses the same SNP technology as DNA TraceBack®, but requires significantly less labor. It’s resulted in what IdentiGEN calls transformational improvements in its process, and reduced the cost of data interpretation by more than 60 percent, according to a company press release.

While that’s clearly a boon for IdentiGEN’s own operations, it’s also yielded a DNA tracking product other labs can now purchase and apply to its own platforms. That’s especially appealing to those in the biotechnology and life sciences industries, IdentiGEN founder and managing director Ciaran Meghen said in a press release.

“While this technology has transformed our internal cost base and will support our continued growth and development in the area of animal and meat product identification in particular, the opportunity to promote our new formulation to a wider user base is an exciting development for our business,” Meghen said.

And that’s good news for Lawrence.

“We’re not just a lab in Lawrence,” Peters said. “We’re a growing lab in Lawrence.”

95 Comments

PredniPharm: prednisone prescription online – how to get prednisone without a prescription

http://lipipharm.com/# Safe atorvastatin purchase without RX

Really informative blog post. Want more.

Reliable crypto exchange for Poland.

I love your approach. It’s creative and effective.cửa hàng điện thoại fpt.

Crestor Pharm: what do rosuvastatin pills look like – CrestorPharm

This is very helpful. Looking forward to more content like this.

Crestor Pharm does medicare cover crestor Crestor Pharm

I appreciate this information. This really made me think.

Thanks for sharing. Super relevant to what I’m working on.

of course like your website but you have to check the spelling on quite a few of your posts. Several of them are rife with spelling problems and I find it very bothersome to tell the truth nevertheless I?ll definitely come back again.

After I originally commented I clicked the -Notify me when new feedback are added- checkbox and now every time a remark is added I get 4 emails with the identical comment. Is there any method you possibly can take away me from that service? Thanks!

Crestor Pharm: CrestorPharm – Order rosuvastatin online legally

Good blog post. The things i would like to bring about is that personal computer memory needs to be purchased when your computer still cannot cope with that which you do along with it. One can add two RAM boards with 1GB each, as an example, but not one of 1GB and one of 2GB. One should check the manufacturer’s documentation for own PC to make certain what type of storage is needed.

We stumbled over here from a different web page and thought I might check things out. I like what I see so i am just following you. Look forward to looking over your web page repeatedly.

Top platform in Spain.

Semaglu Pharm: Rybelsus side effects and dosage – Semaglu Pharm

Semaglu Pharm Online pharmacy Rybelsus SemagluPharm

Great global language accessibility.

Predni Pharm: buy prednisone online canada – prednisone 10mg price in india

http://semaglupharm.com/# rybelsus 3mg weight loss reviews

Another issue is really that video gaming has become one of the all-time biggest forms of excitement for people of nearly every age. Kids enjoy video games, and also adults do, too. Your XBox 360 has become the favorite gaming systems for folks who love to have a lot of activities available to them, in addition to who like to learn live with others all over the world. Thanks for sharing your ideas.

LipiPharm: LipiPharm – Lipi Pharm

Semaglu Pharm SemagluPharm SemagluPharm

Interesting perspective. Can you elaborate on this part?

CrestorPharm: rosuvastatin efectos secundarios – CrestorPharm

Nothing beats people coming together to talk about their views, especially in the welcoming space at sex 9+ 88aa. Love the website, keep up the good work!

https://semaglupharm.com/# is rybelsus a pill

Best website I’ve seen in Ireland.

https://crestorpharm.shop/# Crestor Pharm

Reliable and consistently good.

Order rosuvastatin online legally: Crestor Pharm – CrestorPharm

CrestorPharm Affordable cholesterol-lowering pills Crestor Pharm

Predni Pharm: Predni Pharm – can you buy prednisone over the counter in usa

It’s wonderful when folks gather and discuss their thoughts, similar to the engaging conversations at sex tre em 88aa. Awesome website, keep it going!

https://semaglupharm.com/# SemagluPharm

Matcha Swap

How to Use Matcha Swap: A Step-by-Step Guide for DeFi Traders

Matcha Swap

Hyperliquid

Matcha Swap

Fantastic article post.Really thank you! Much obliged.

MultiChain

Hyperliquid App

How to Use Matcha Swap: A Step-by-Step Guide for DeFi Traders

MultiChain

MultiChain

Matcha Swap

prednisone 5 mg tablet cost: PredniPharm – Predni Pharm

LipiPharm Atorvastatin online pharmacy lipitor generic price

MultiChain

Thanks for the thoughts you have contributed here. In addition, I believe there are some factors which keep your car insurance policy premium lower. One is, to consider buying autos that are from the good listing of car insurance businesses. Cars that happen to be expensive will be more at risk of being robbed. Aside from that insurance is also in line with the value of your car or truck, so the higher priced it is, then higher a premium you make payment for.

Hyperliquid

SemagluPharm: difference between compounded semaglutide and ozempic – Semaglu Pharm

What Is Hyperliquid?

MultiChain

MultiChain

https://semaglupharm.com/# Affordable Rybelsus price

Matcha Swap

MultiChain

very nice post, i certainly love this web site, keep on it

I’m amazed, I have to admit. Seldom do I encounter a blog that’s both equally educative and interesting, and let me tell you, you’ve hit the nail on the head. The problem is an issue that not enough men and women are speaking intelligently about. Now i’m very happy that I stumbled across this in my hunt for something concerning this.

Matcha Swap

Matcha Swap

https://lipipharm.shop/# atorvastatin 40 mg uses

Order cholesterol medication online crestor vs. lipitor Online statin drugs no doctor visit

Crestor Pharm: does crestor cause fatigue – CrestorPharm

https://semaglupharm.com/# semaglutide for pcos

This is a topic that’s near to my heart… Take care! Exactly where are your contact details though?

atorvastatin recall 2018: Affordable Lipitor alternatives USA – atorvastatin 80 mg price

Lipi Pharm LipiPharm Affordable Lipitor alternatives USA

http://semaglupharm.com/# Semaglutide tablets without prescription

п»їBuy Crestor without prescription: Online statin therapy without RX – Generic Crestor for high cholesterol

Enjoyed every bit of your blog post.Really looking forward to read more.

https://prednipharm.shop/# Predni Pharm

compounded semaglutide: can semaglutide cause headaches – FDA-approved Rybelsus alternative

atorvastatin (lipitor) 40 mg tablet another name for lipitor nursing considerations for atorvastatin

https://semaglupharm.com/# Semaglu Pharm

Lipi Pharm: Generic Lipitor fast delivery – Generic Lipitor fast delivery

http://semaglupharm.com/# SemagluPharm

Lipi Pharm LipiPharm when should lipitor be taken

SemagluPharm: how many units is 2.5mg of semaglutide – saxenda vs rybelsus

I just like the helpful info you provide for your articles.

I will bookmark your blog and check once more right here regularly.

I am somewhat certain I will be informed many new stuff proper

right here! Good luck for the next!

Lipi Pharm: LipiPharm – atorvastatin 40 mg tablets

Fabulous, what a weblog it is! This website provides valuable facts

to us, keep it up.

Mobile experience is outstanding.

Lipi Pharm does lipitor LipiPharm

Atorvastatin online pharmacy: LipiPharm – Atorvastatin online pharmacy

https://lipipharm.shop/# No RX Lipitor online

Over-the-counter Crestor USA: crestor pris – crestor liver enzymes

https://semaglupharm.shop/# Semaglu Pharm

CrestorPharm Crestor Pharm п»їBuy Crestor without prescription

SemagluPharm: SemagluPharm – semaglutide 3 month results

Crestor Pharm: CrestorPharm – Crestor 10mg / 20mg / 40mg online

I was more than happy to uncover this page. I need to to thank you for ones time due to this fantastic read!! I definitely appreciated every little bit of it and I have you bookmarked to check out new things on your website.